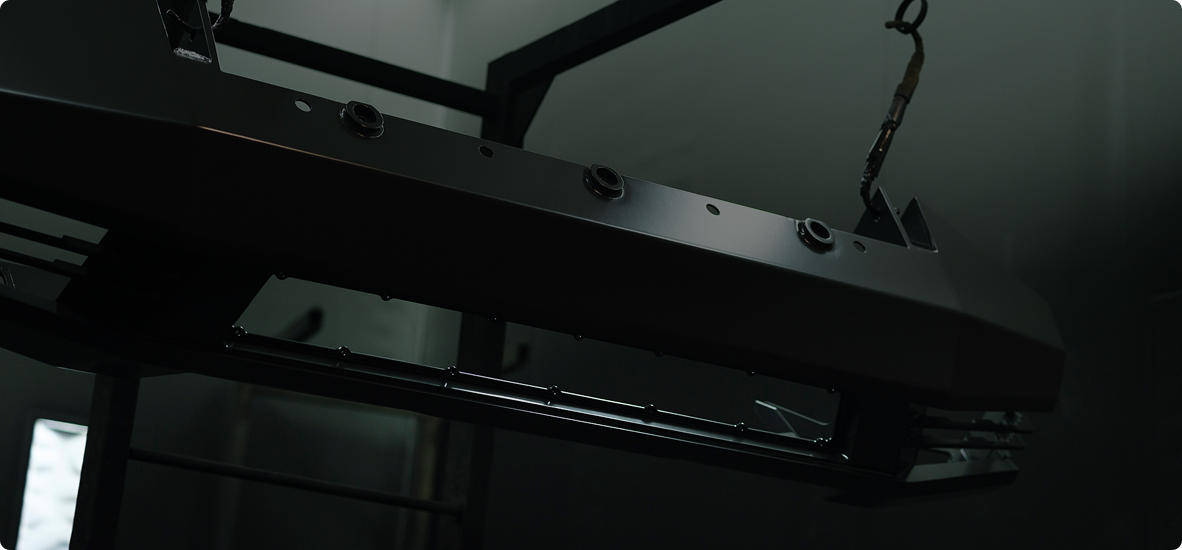

We perform high-precision bending and punching of metal structures in accordance with the customer’s technical requirements. We process steel, aluminum and other metals, giving parts the necessary shape while preserving the structure of the material.

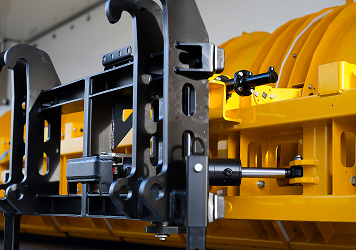

With the help of modern presses and bending equipment, we can make parts of any complexity at our plant, including curved components used for auto parts, supports, panels and structural units. The processes are automated so that we can maintain stable quality even in series production.

We select the optimum processing parameters for each specific project to ensure precise geometry, minimum tolerance and high durability of the finished product. Finished parts go straight to the next operation – welding, machining or painting –which speeds up order fulfillment.

Our equipment:

DURMA, AMADA, CINCINATI, COLGAR, GETENES, etc. equipment is intended for the sheet metal bending. Computerized control makes it possible to carry out bending operations (for one item) without the repeated press adjustments. Metalworking parameters:

- Material thickness to 12 mm;

- Maximum length (according to specifications and thickness) – to 3500 mm

- Rolling to 4000mm length.