The Beginning

Registration of the company in Latvia, first products manufactured.

Launch of cooperation with major customers from Norway.

ESP EUROPEAN STEEL PRODUCTION SIA

Rūpnīcu Street 4, Olaine, Olaines District, LV-2114, LatviaReg.#: LV40103266905

Rietumu Banka

SWIFT: RTMBLV2X

Bank account: LV41 RTMB 0000602801868

ESP European Steel Production was established in Latvia in 2010.

We manufacture metal components for the aerospace, heavy and automotive industries, civil engineering, transportation and defense sectors.

Our technologies makes it possible to provide full cycle production, from raw material preparation to surface finishing and packaging - including cutting and bending, assembly, welding, machining and painting. Our finished products are ready for further assembly and installation.

All products are manufactured at our plant in Latvia and have European quality certificates.

Registration of the company in Latvia, first products manufactured.

Launch of cooperation with major customers from Norway.

Gradual increase in production volumes and turnover.

Regular cooperation with major customers:

New equipment put into operation: a laser cutting machine and a 400-ton hydraulic press brake.

Electrostatic painting equipment put into operation.

Launch of cooperation with new customers:

Start of operation of CNC machining center HAAS VF-4 opens up new metal processing opportunities.

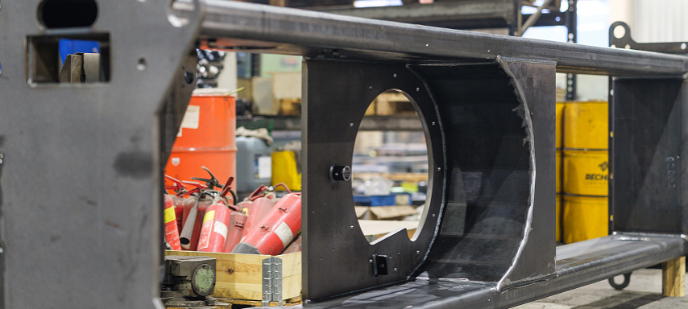

Start of serial production of snowplow parts for Øveraasen AS.

The company’s turnover amounts to close to EUR 6 million.

122 different structural parts for snowplows produced.

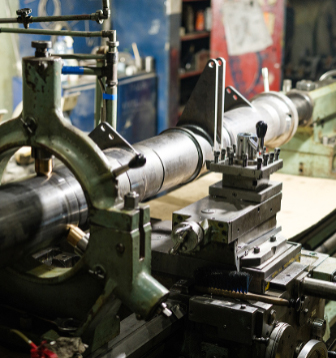

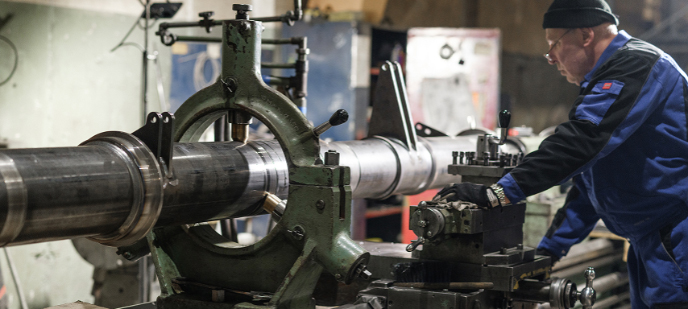

Horizontal machining center FERMAT WFC-10 is put into operation, increasing technological capabilities of ESP.

Start of deliveries of hydraulic tanks and auxiliary components to Brunvoll AS (Norway).

Serial production and supply of components for a new generation of articulated dump trucks for Doosan Infracore (Norway).

Ensuring regular product shipments to all customers during the COVID-19 pandemic.

Supply of various components for airfield snowplows to Øveraasen AS (Norway).

Start of operation of a CNC lathe and a robotic welding cell.

The company’s turnover hits EUR 7 million.

Production volumes continue growth.

New equipment put into operation:

The company’s turnover exceeds EUR 8 million.